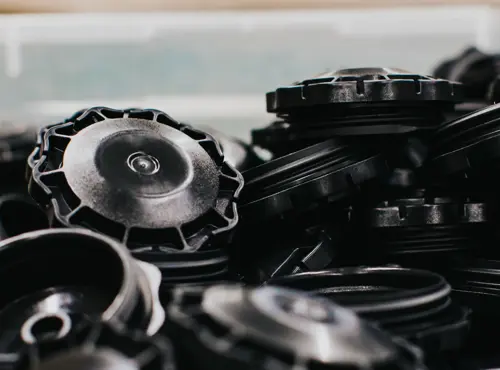

Injection moulding

Injection moulding allows the high precision manufacture of components in complex forms for both small scale and large scale production. It is a method that enables the fabrication of everything from really small parts that weigh just a few grams, to parts that are significantly bigger and significantly heavier.

This means a huge amount of freedom and very few limitations in respect of what you can do. Injection moulding is particularly suited to large scale production, as the unit cost can be kept to a level that is economically advantageous.

Material specification

We can produce plastic components with an injection weight from 0.1 to 3000 g. Our machines are equipped to handle processing of virtually all types of plastic materials. Our machine park includes injection moulding machines for one or more material types in the same part.

| Materials | Areas of use |

| Polyethylene (PE) | Plastic bags, bottles, containers |

| Polypropylene (PP) | Food containers, glass boxes, packing |

| Polystyrene (PS) | Food packaging |

| Polyethylene terephthalate (PET) | PET bottles, cans, packaging |

| Polybutylene terephthalate (PBT) | Electronic connectors, enclosures |

| Acrylonitrile Butadiene Styrene (ABS) | Cases, computer monitors, car interiors |

| Polymethyl methacrylate (PMMA) | Lenses, taillights for cars |

| Polycarbonate (PC) | Ceiling lamps, sunglasses |

| Polyamide 6 (PA 6) | Cases, dipsticks |

| Polyamide 6 glass-fibre reinforced (PA 6 GF) | Oil containers |

| Polyamide 66 (PA 66) | Mounting brackets, sealing clips |

| Polyamide 66 glass-fibre reinforced (PA 66 GF) | Protective enclosures, Brackets |

| Thermoplastic elastomer (TPE) | Pedal covers, Sealing Gasket, Pacifiers |

| Polyphthalamide, semi-aromatic PA (PPA) | Good alternative for metal replacement |

| Polyvinyl chloride (PVC) | Pedal covers, PVC pipes, sewage pipes |

| Acetal plastic (POM) | Plain bearings, clips, cogs |

| Polyphenylene sulphide (PPS) | Pump parts, heat shields |

How can we help you? We are on hand to support you, answer your questions, and to tell you more about what our services can do for you and your business. The easiest way to get in touch is by phone or e-mail. We look forward to hearing from you soon!

Contact us