2021-04-06

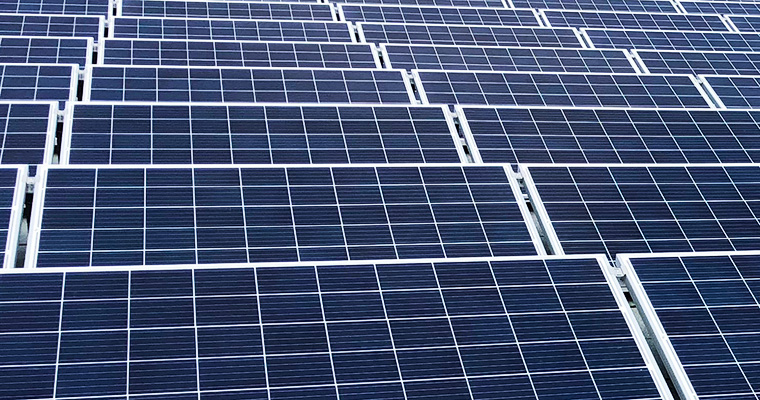

Choosing types of energy with as small an environmental impact as possible is one of the investments being made in our work for a sustainable development. In our environmental work, we are taking yet another step forwards by installing solar cells on the roof, to produce electricity for our operations in Smålandsstenar.

The solar cells have a capacity of 320 kW and they sit on the roof areas that have a suitable construction.

2021-02-26

The personnel are the Weland Group's most important resource. For this reason, the Group has initiated a health and wellness venture for all employees that will strengthen both the health and the solidarity in the workplace. The venture started in the spring of 2020, and the overriding goal is to have fit and healthy employees.

Weland Plastic, together with our sister companies in Smålandsstenar, have carried out many activities. We have had the opportunity to try out running exercise, yoga, paddling, quiz walks and walks in nature. On many of these occasions, we have also been inspired by skilled instructors. To give the employees something to train for, and look forward to, the next major goal will be the Welandstafetten relay race, which will be held in autumn 2021. The relay race will be run by teams of five people who walk, jog or run their leg.

2021-02-01

For Weland, environmental and sustainability work is an important and high-priority issue. Sustainability is, among other things, about choosing the type of energy that gives as little environmental impact as possible by making energy-efficient choices of everything from machines to heating and lighting.

When it comes to heating and cooling our facilities and machines, we have gone from fossil fuels to cooling and heating that now takes place through free cooling and geothermal heating. By constantly developing our production processes for better material and energy utilization, we achieve efficient environmental work.

Weland Plastic is taking another energy-saving measure and is now moving towards a greener future. We have now received our first electric car and we will gradually replace our fleet of cars with only rechargeable vehicles.

2020-12-08

We have installed a new, fully automated, raw material system from Piovan, delivered by KD Feddersen, which supplies our machines with plastic granulate in an efficient and environmentally friendly way.

The system is managed and monitored by Winfactory, providing us with continuous monitoring of the process while making life easier for our employees.

2020-11-03

Weland Plastic has invested in three new injection moulding machines, two 160 metric tonnes and one 110 metric tonnes, with associated full servo robots with the latest font. The machines will be equipped with vision systems for inspecting parts as well as robots for feeding encapsulation parts. The equipment is tried and tested and has already been used with our machines before. Read more about what we can offer in the field of injection moulding.

2020-10-07

Weland Plastic is continuing to invest and it has installed a new measuring machine from German Wenzel. The measuring machine is a Wenzel XO87 Liberty and it is equipped with the latest software. The measurement range along the axes is X 800 mm, Y 1000 mm and Z 700 mm. The new machine has maximum one variation of 1.7my during measurement and is equipped with a 5-axis probe head for fast and accurate measurement.

A new measuring machine creates opportunities for expanding our measuring capacity and increasing our flexibility allowing us to better satisfy our customers' needs for injection moulded articles.

2020-09-14

The expansion of our premises is now complete. The new total factory area at Weland Plastic is 15,000 m², split into three production halls equipped with overhead cranes that can handle tools weighing up to 12 tonnes.

The expansion of Weland Plastic's premises has taken place in two steps, and started during the summer of 2019. In our new factory area, we have a materials hall and two finished goods stores, built based on an efficient FIFO flow. The last step in the expansion is for the injection moulding of plastic parts in engineering moulded goods as well as store for finished items.

In connection with the newly built storage halls, the loading bay was also extended to double the area, with both rear and side loading in sheltered surroundings. A canopy for packaging adjoining the production area has been extended to approx. 700 m². The design and build contract is for 7600 m².

2020-03-19

Weland Plastic has invested in an additional vertical storage lift from its sister company Weland Solutions. The vertical storage lift, a Compact Lift 3660, is placed on the newly built warehouse premises.

"The storage lift is connected to our business system. Thanks to the investment, we save storage space and can handle goods efficiently," Peo Axelsson, CEO Weland Plastic, says.

Moreover, together with Weland Solutions, they have developed a new plastic product, in the shape of a plastic box that is used as storage equipment in their vertical storage lifts. Now, Weland Solutions can deliver a complete storage lift with its own tailor-made storage equipment.

2019-11-04

Weland Plastic inaugurated its new warehouse in October. When the company decided to extend its production facility, it also agreed that a new warehouse should be built. This would allow for an optimal flow of work through the factory; raw materials enter one end of the factory and final plastic parts are stored at the other end, before being loaded and shipped out.

A deep stacking storage area has been installed inside the new warehouse to facilitate FIFO management.

2019-08-14

At Weland Plastic, the construction of a new production hall and a new warehouse is underway. Altogether, the new extension will be 4,200 m².

The move to the new warehouse and production hall will take place during the autumn.

2019-08-07

Weland Plastic has increased its machinery fleet by adding two more hybrid machines – a 220 tonne and a 500 tonne machine of the make Engel. The two new injection moulding machines are helping to increase the capacity in the production.

With more machines and greater production capacity, Weland Plastic can satisfy its customers' needs even better when it comes to injection moulded articles.